New Partnership Announcement

Chemical storage installation

After a process of supplier evaluation, Chem Resist was invited to work directly with the client and indirectly through sub contracts in designing suitable chemical storage and distribution equipment.

Utilising the unique Thermoplastic Spiral Winding process manufactured from the best available material, HDPE PE100 RC, eight Chemical Storage Tanks with a total capacity of 250,000 litres were delivered and installed on site.

Chemical transfer was also part of the Chem Resist scope. Specifying against a range of operating parameters thirty pumps from the Chem Resist range ‘Chem Free’ Thermoplastic Centrifugal Magnetically Coupled Units and ‘Almatec’ Air Operated Diaphragm were supplied and installed.

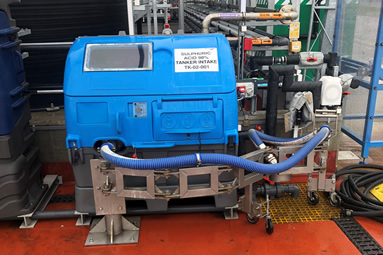

As a business at the forefront of chemical distribution, any new site has to consider the full extent of risk to personnel and the environment associated with chemical transfer, in particular uncontrolled spillage. To significantly reduce this risk the Chem Resist ‘ChemiGuard’ range was utilised on all tanker offload points providing operator protection, security and integral spill prevention.

The relationship continues to mature with new projects being undertaken at alternative existing sites throughout the UK.