Plastic tanks for mixing chemicals

Chem Resist thermoplastic chemical mixing tanks offer excellent chemical resistance; we specialise in providing solutions using the mixing recirculation method to mix chemicals.

Our Chemical Mixing Tanks are manufactured in Spiral Wound Thermoplastics such as Polypropylene and High-Density Polyethylene (HDPE) and offer significant advantages including: –

- A broad range of chemical resistance

- Coned, Sloping or Flat Base choices

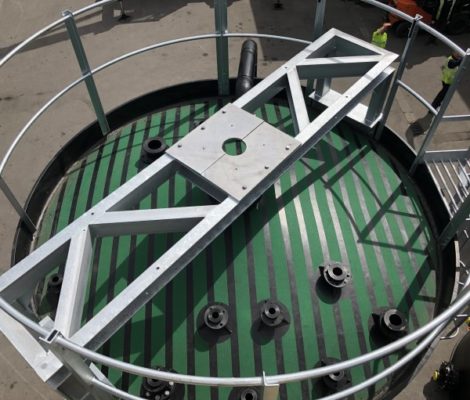

- Integral Mixers and Mixer Support Gantries

- All-Plastic internal Mixer Baffles

- Complete Static Mixing design facility

Our in-house manufacturing allows us to offer vessels up to 4.3m diameter and capacities up to 100m3.

Chem Resist’s unique spiral winding process means we are not restricted to fixed diameters or heights – so we can manufacture what you need rather than what we can make!

Traditional Chemical Mixing

Mixing in a vessel usually implies a tank with a large agitator and associated motor suspended over the top of the vessel, with the mixing propellor extending down into the liquid. Significant support steelwork is often required. Problems associated with this arrangement are more apparent when the liquid is of a highly corrosive nature, requiring exotic materials or expensive coatings. Access to the shaft and propellor can be difficult, as can working at height for any maintenance work to the motor. In some situations, this is the only option and one we are able to provide solutions to with our chemical mixing tanks and extensive experience.

Chemical Mixing Recirculation

Chemical mixing recirculation involves the promotion of fluid movement and subsequent mixing of the liquid, by drawing off a portion of the liquid through a pump and reintroducing this as a jet through a high-velocity nozzle. This action causes the bulk liquid to become entrained in the flow of the jet and so inducing the turbulent mixing action. Further enhancement of this process can be gained by exchanging the nozzle for a venturi eductor. The eductor employs a venturi throat, which entrains approximately four times the quantity of the pumped flow, significantly enhancing the mixing process with the increased flow rate, resulting in shorter mixing times.

Advantages Of Chemical Mixing Recirculation

- Increased safety as there are no moving parts within the chemical mixing tank

- Moving parts at low level, with maintenance possible without draining the vessel

- Support steelwork eliminated as a requirement

- Fully corrosion-resistant chemical mixing

- Reduction in costs with baffle removal

- Virtually no wearing of eductors, resulting in long service life

- CFD modelling helps to eliminate stagnant areas

- Suspensions can easily be maintained

- Fuming solutions can be totally enclosed in the vessel

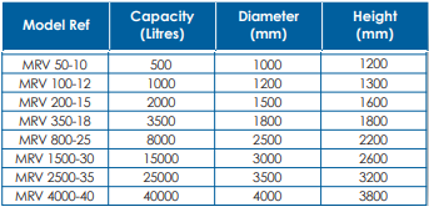

Chemical mixing tank models

Whilst Chem Resist offer bespoke solutions, we do have a range of standard chemical mixing systems available. These comprise a purpose-designed thermoplastic chemical mix tanks, sized to the ideal proportions for this mixing technique. The pump and venturi eductor system which complete the package are sized to give a practical liquid mixing time.

Enquire about this product

If you have a technical specification available, please complete our technical quotation form and we will be able to provide you with an accurate quote.

Click here to send your full specification

Alternatively, contact us on +44 1924 499466 or [email protected].

Download the white paper:

“THE CHEMICAL STORAGE CARBON FOOTPRINT”

If you’re interested in learning more about Chemical Storage tanks manufactured using the Spiral Wound method – how they can be used to benefit your organisation and the environment when compared to the alternatives – download our white paper to learn more about the carbon footprint of chemical storage.

Prepared by Chem Resist Sales Director Gary Smith and Technical Manager Stephen Menzer, the white paper breaks down both the business and environmental case for spiral wound manufacturing.