De-Icer Storage System

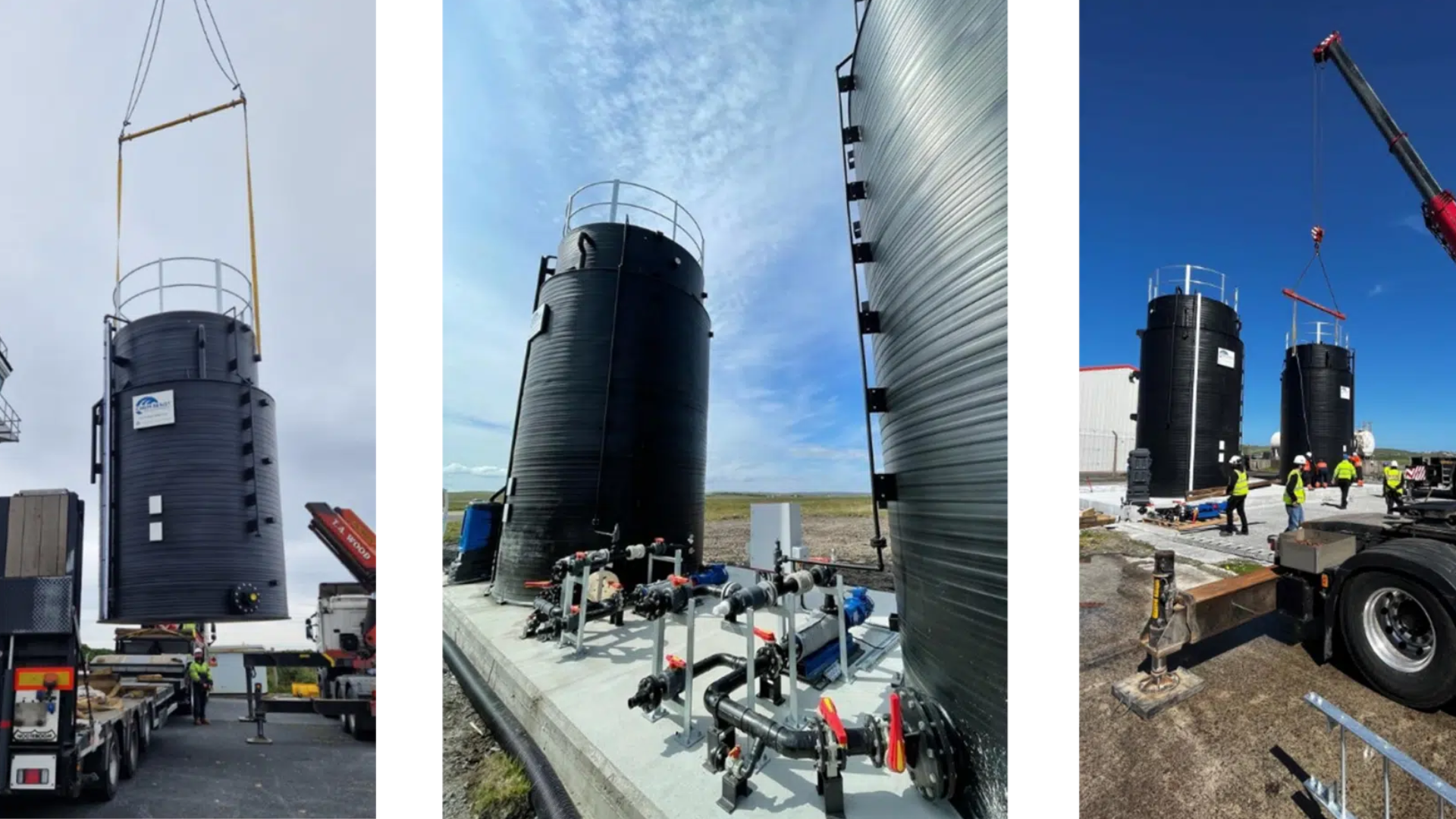

Manufacture and installation of runway de-icer thermoplastic storage systems for 5 sites across Highlands and Islands Airports.

Operating 11 airports across Scotland and the Hebrides, including locations on the Shetland and Orkney Islands, Highlands and Islands Airports Limited (HIAL) have a responsibility to keep these remote parts of Scotland connected, as well as a responsibility to meet and exceed best practice in terms of environmental protection.

To keep the runways free of ice, ECO-GEN runway de-icer – an aqueous potassium-based solution needs to be stored in large quantities at each of the locations, demanding storage solutions that can withstand extreme local weather, including temperatures as low as -20°C at some of the most Northernmost sites.

As part of an ongoing development project, HIAL required the manufacture and installation of seven de-icer storage solutions across five of its sites. Chem Resist were selected to fulfil the tender based on our extensive experience delivering chemical storage solutions that not only withstand harsh environments, but also meet exceptionally high environmental and safety standards.

Customer Requirement

- Replacement of existing rubber-lined steel tanks and IBCs

- One 30m3 de-icer storage system at each of the Tiree, Islay and Campbeltown sites

- Two 55m3 de-icer storage systems at each of the Stornoway and Sumburgh sites

- Remove the need for operatives to manually handle ECO-GEN

- Provide environmental protection against potential containment incidents

Project Challenges

- Local ferry transport had to be used to move the components of the storage systems, including the large capacity tanks, so the tanks were manufactured to meet HIAL’s capacity requirements and fit on the ferries.

- The project plan had to accommodate the islands ferry timetable.

- Working airside at various sites demanded security checks for all the on-site teams.

- Narrow roads and tight bridges at some sites created logistical restrictions that required careful route planning.

- Although thermoplastic materials are proven down to -40°C, the entire storage system had to be operational down to the same low temperature, including pipework, valves and individual O-rings.

Installation pictures at (LtoR): Islay, Stornoway and Sumburgh

Chem Resist Solution

The Chem Resist Process Plant team developed a solution that utilised Bunded Spiral Wound Chemical Storage Tanks to provide protection against any potential loss of containment.

ChemiGuard Pressurised Offload Cabinets were also introduced to provide protection during the offload process and protecting the environment and providing operator safety.

Bespoke pumps were sourced for the project, and Plast-O-Matic valves were used to handle the high pressure within the system.

After initial site surveys, manufacture took place at Chem Resist’s Dewsbury headquarters, with additional preparation work done there for the ChemiGuard cabinets, pipework and pumps to minimise disruption at the HIAL sites. Thanks to this preparation work and careful planning, each system was installed in a maximum of just two days.

Chem Resist have worked with HIAL consistently since 2012, making this the sixth project undertaken by the two organisations. This extensive, multi-site project involved the majority of Chem Resist’s 50-strong team and was led by Project Engineer Ian Ward.

Back to Case Studies