Polypropylene

Polypropylene was first polymerised in 1951, with subsequent commercial production in 1957. It is currently the 2nd most important plastic in terms of revenues. Polypropylene is a very useful material in Thermoplastic Vessel manufacture, where higher temperatures are being used in Chemical Processes, coupled with maintaining excellent Chemical Resistance.

A summary of Polypropylene’s properties are;

- A broad range of chemical resistance

- A specified design life with unlimited fill and empty cycles

- polypropylene pH resistance across the full range

- Suitable for use at higher temperatures

- Compliant with EU Directive 2002/72/EU (Food grade Plastic Materials) and WRAS approved

Material Specification

Polypropylene

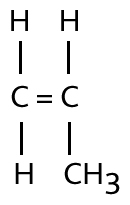

Polypropylene is manufactured by the polymerisation of Propylene. The structure of Propylene is given in figure 1.

The structure of Polypropylene is said to be ‘partially crystalline’. This means that within the macromolecules there are both crystalline and amorphous regions. The crystalline structure gives rise to high strength whilst the amorphous regions retain greater mobility. Therefore Polypropylene is one of a number of thermoplastics that have a relatively high strength and stiffness, even at reasonably high temperatures.

By varying the molar mass and modifying the type of polymer (Homopolymer, copolymer, elastomer blend) a range of grades suitable for many applications can be produced.

Homopolymers have high hardness, stiffness and tensile strength and satisfactory toughness. By copolymerisation with lower olefins – preferably ethylene – toughness is increased, particularly at low temperature. Hardness, stiffness and tensile strength thereby decrease.

The cylinders of Chem Resist vessels are extrusion wound in virgin Copolymer Polypropylene. All materials used comply with EU Directive 2002/72/EU (Food grade Plastic Materials).

This Beige Grey material, RAL 7032, exhibits excellent corrosion resistance to a wide range of inorganic and organic acids and bases.

| Properties of Polypropylene | |||

| Property | Test Method | Units | Value |

| Nominal Density | DIN 53479 | g/cm3 | 0.91 |

| Breaking Strength | DIN 53455 | N/mm2 | 30 |

| E-Modulus through bending (60s – value) | DIN 53457 | N/mm2 | 900 |

| Notched Impact Strength | DIN 53453 | kJ/m2 | 25 |

| Hardness | DIN 53505 | Shore D | 67 |

| Linear Coefficient of Thermal Expansion | ASTM D696-44 | 1/K | 1.6…1.8 x 10-4 |

| Thermal Conductivity | DIN 52612 | W/m K | 0.22 |

| Working Temperature without Mechanical Pressure | DIN 53446 | ºC | -20 TO +120 |