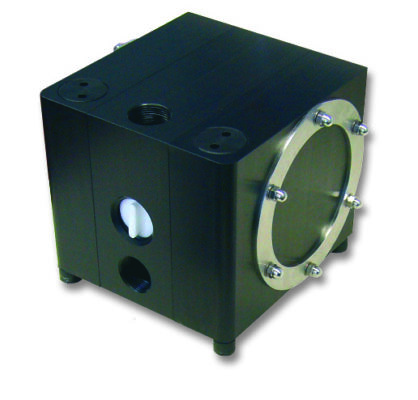

Plastic Air-Operated Double Diaphragm (AODD) Pumps for low to medium duty applications

The Almatec CXM series of AODD pumps are used as general-purpose pumps for low to medium performance applications and also as drum and IBC pumps.

Available with a wide range of connections to allow precise adjustment of the pump to the specific application. Four pump sizes are available with NPT connections and three pump sizes with BSP connections. There is also a choice between ball and cylinder valves with easy conversion from each other. Ball valves are ideal for liquids containing particles, cylinder valves for superior suction lift for clean liquids.

Flow optimisation in the product channels ensure high performance and gentle pumping. The CXM series adapts the ring-tightening structure which is found in the Almatec E-Series. Housing parts are tightened to each other by housing bolts tightened against a diaphragm sized ring on each side, giving an even distribution of the housing bolt force and an increase permissible bolt torque, improving pump safety.

Available in machined PE with FDA and ATEX conformity to 2014/34/EU

Dry run capability and solids handling are further features.

Performance Data

- Port size (inches): 3/8” to 1¼” (NPT); ½” to 1½” (BSP)

- Max particle size (ball valve only) (mm): 1.5 to 4

- Max temperature (°C): 70

- Max capacity (m3/h): 0.7 – 7.8

- Suction head wet (mWC): 8 – 9

- Suction head dry (cylinder valves) (mWC): 0.7 – 4.5

- Suction head dry (ball valves) (mWC): 0.5 – 3

Features and Benefits

- Simple yet robust pump with reliable Almatec construction

- Maintenance and lubrication-free air control system PERSWING P® reduces operating costs

- High pump safety due to innovative ring-tightening structure

- Dry run capability and solids handling (ball valve only)

- No drives, no rotating parts, no shaft seals – no internal wear

- FDA and ATEX conformity to 2014/34/E

- CXM 10 – NPT ⅜” – 7 bar

- CXM 20 – NPT ½” – 7 bar

- CXM 25 – BSP ½” – 7 bar

- CXM 50 – NPT ¾” – 7 bar

- CXM 55 – BSP 1″ – 7 bar

- CXM 130 – NPT 1¼” – 7 bar

- CXM 135 – BSP 1½” – 7 bar

- Housing: PE conductive

- Diaphragms: EPDM, PTFE/EPDM, NBR

- Gaskets: EPDM, PTFE/EPDM, NBR

- Ball valves: EPDM, PTFE, NBR, stainless steel

- Cylinder valves: PE

- Drum pump kit (CXM20 & CXM50)

- Transport cart

Enquire about this product

Send a message to the Chem Resist sales team for more information.

Alternatively, contact us on +44 1924 499466 or [email protected].

"*" indicates required fields