Bespoke fabrications for your requirements

Introducing a new manufacturing process, refining an existing one or replacing old critical equipment can generate one-of-a-kind requirements involving design, build and installation services to meet very precise demands.

Our Pipework Systems team have experience of working with customers to create custom fabrications and working hand-in-hand with customers to establish their exact requirements and create solutions to fit with existing and new processes.

We specialise in using thermoplastics due to their inert nature when dealing with some of the most aggressive chemicals. Specifically, we use Corrosion Resistant Polypropylene and High-Density Polyethylene (PE100-RC). We also provide solutions using PVC and PVDF.

Our Pipework Systems team also work alongside our Process Plant and Fluid Transfer divisions to provide Turnkey Project Services to design, manufacture and install complete storage and transfer solutions for corrosive and aggressive chemicals.

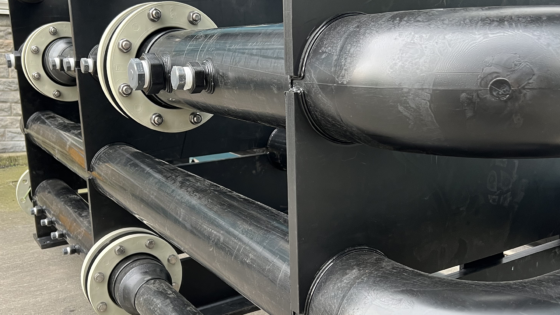

Flocculators

Flocculators are primarily used in the treatment of water and wastewater to separate impurities by allowing fine particles to amass together, creating larger flocs, which are easier to remove. This removal helps to purify the water making it cleaner.

A flocculator includes a configuration of pipework through which the water is mixed with an agent typically a coagulant or flocculant to facilitate the separation process. We design and build each flocculator to maximise the possible interaction between the water and the agent as the water passes through the configuration of pipework. PH probes can also be inserted into the pipework to help measure levels within the water.

We can design and build flocculators to your specification and size, depending on the application, flow rate and treatment required. Typically manufactured in HDPE (32mm to 160mm diameter) to provide excellent chemical resistance and durability.

Dosing and Filling Systems

We have built custom Dosing and Filling Systems for our customers in a broad range of industries including food and beverage, energy, and chemical manufacturing and processing.

A Dosing System would be required to introduce a specified amount of an agent or chemical at a specific point in a production process.

The Filling Systems we design allow chemicals to be transferred from bulk supply into smaller tanks or IBC’s and then into smaller containers for sale to industry or consumers.

Every Dosing and Filling System we design and manufacture considers the chemical, supply, required flow rate, dispensing and handling requirements.

“I also wanted to let you know how professional Tom was when on site. Polite, courteous as well as precise with his work. Definitely a credit to your company.”

Ryan Brennan, Recipharm

Pickling Line

Pickling is the process of cleaning metal parts as they move through a manufacturing or finishing process. We have designed and built custom cleaning systems to remove scale, rust and surface oxides using acidic solutions known as pickling liquor. We have designed and built Pickling Lines to clean metal components and also wire rods prior to wire drawing.

a) Wire Drawing – prior to the wire drawing process, the wire rod is pickled to ensure the removal of surface contaminants. This then means the lubricant used to help draw the wire can completely adhere to the rod surface.

b) Component Cleaning Systems – once a metal component has been produced, prior to it moving to final finishing, it would move through the pickling line to remove any surface residue such as dirt or weld debris.

We are also able to provide liners for existing stainless steel pickling tanks to provide a chemically resistant layer to the tank’s interior walls.

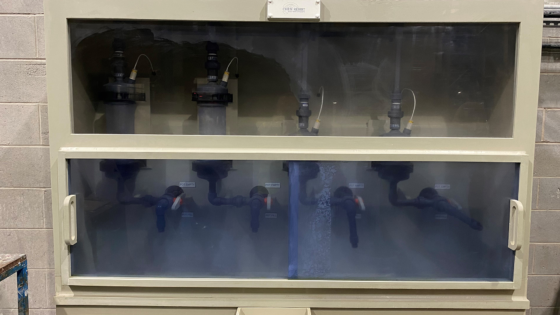

Fume Extraction

Cabinets for fume extraction, often called fume hoods or fume cabinets are used to contain and remove hazardous and noxious fumes from applications and protect the wider environment and operators. Fumes (typically from Hydrochloric Acid or Nitric Acid) are drawn from inside the cabinet and can then either be filtered and recirculated or extracted where they can be scrubbed to leave clean air. For details of our Fume Scrubbers please visit here.

Vacuum Vessels

Vacuum vessels (also known as vacuum chambers or tanks) are used to create and control a vacuum or low-pressure environment, which when combined with temperature and pressure, create a specific environment for research and experiments and precise manufacturing processes. We design and build vacuum vessels from thermoplastics to give them the necessary stability and strength to maintain the required conditions.

The Vacuum vessels pictured here are being used as part of a vacuum filling system.

Enquire about this service

Alternatively, contact us on +44 1924 499466 or email [email protected].

"*" indicates required fields